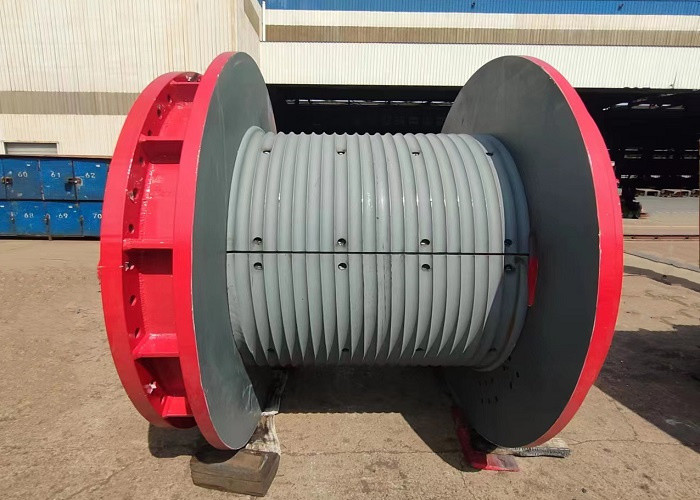

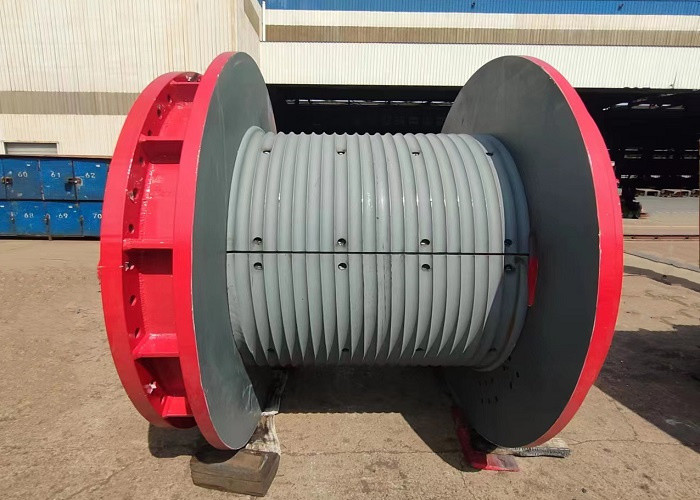

Grooved Sleeves(Shell)

Split-sleeve consists of a pair of outer shells that are bolted or

welded onto a smooth drum. We can manufacture spiral groove and

lebus groove.

The split-sleeve depends on the drum’s size, wire rope diameter and

length. The sleeve is composed of a sleeve cut in half, which can

be fixed to a smooth drum by welding or bolted fastening. If we

want to make a sleeve, we need only the drum size , wire rope size

, and the number of winding layers, We can customize production

based on this data. The scope of application is the same as that of

lebus drum.

Successful cases

Our production of lebus grooved drum, and winch rope groove plate

assembly, now widely used in petroleum machinery, mining machinery,

ships, ports, lifting machinery, lifting machinery, etc., and with

daqing oilfield, shengli oilfield, dagang oilfield, zhongyuan

oilfield, liaohe oilfield oilfield, nanyang oil factory, big

companies such as sany, established a long-term, stable relations

of cooperation, Products are also exported to the United States,

Canada, Brazil and so on. Our factory can design and manufacture

various specifications of folding rope groove tube, rope groove

plate and winch according to the requirements of users, but also

can provide on-site installation.

What is the welding process of steel sheet drum group?

Adopting plate blanking roll cylinder and weld longitudinal welds,

checking longitudinal welds and geometric dimensions of cylinder

(diameter, length, inner diameter ellipticity tolerance, etc.). For

large diameter cylinder, adding welding process reinforcement and

machining annular groove of cylinder. There are requirements for

the process of roughing the cylinder outside the circle to process

the outer circle, cylinder length welding (namely ring seam

welding). For the two ends of the cylinder need to add welding

process reinforcement according to the process regulations, and

check the quality of ring welding and machining allowance, cylinder

length processing and both ends of the stop or groove processing

and welding cylinder end flange plate, shaft, inner support ring,

etc.

some Technical Parameters

No: | Wire diameter(mm) | Pulling Force(KN) | Rotation Direction | Drum Diameter(mm) | Drum Length(mm) |

1 | 3~8

| 3~10 | Lefthand,Righthand | >160 | <1000 |

2 | 10~16

| 12~20 | Lefthand,Righthand | >320 | <1000 |

3 | 18~24

| 20~80 | Lefthand,Righthand | >480 | <1000 |

4 | 26~32

| 100~120 | Lefthand,Righthand | >640 | <1000 |

5 | 34~40

| 150~200 | Lefthand,Righthand | >800 | <1000 |

6 | 42~50

| 240~400 | Lefthand,Righthand | >1000 | <100 |

Our Service

a.Our company specialized in design and produce various types of

electric and hydraulic anchor windlass , mooring winch, luffing

crane and boat plane and rack, winch, engineering winch, cable

winch and towing winch(The main drum is used grooved drum).

b. One year of warranty.

c. The engineer can provide overseas service.

d. Quick and responsible after-sales service.

e. Very competitive price.

f. Before sending the goods, we will test and adjust, so you can

use directly when you get it.

g. Operation video & instruction will be sent to clients, to help

them use the sleeves better. Additionally, our company provides

technical support and fittings for life.

h. Any problems occur while using, professional advice will be

offered.

i. All kinds of frequently used parts are supplied all the year

round.