20 Ton Best Design Ship Variable Speed Winch with Spooling Device

Product introduction

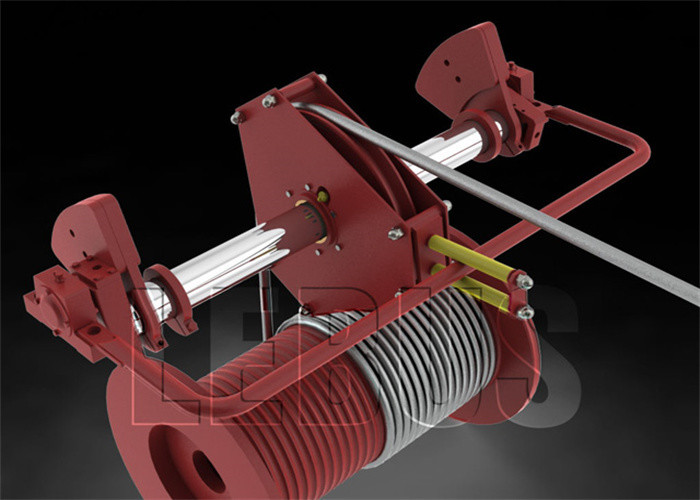

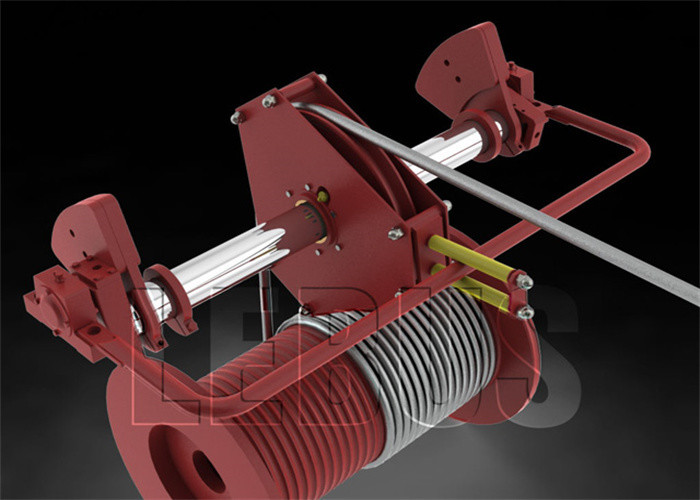

The manual winch with cable arrangement device includes winch

module, transmission module and cable arrangement module. The cable

arrangement module includes reciprocating lead screw, optical

shaft, transmission nut, guide wheel, guide fixed rod and fixed

plate.

The reciprocating lead screw and optical shaft are arranged in

parallel with the drum shaft in the winch module, and the drum

shaft is connected with the reciprocating lead screw through the

transmission module, Drive the reciprocating lead screw and the

drum transmission shaft to rotate together according to a certain

transmission ratio, the transmission nut is rotationally connected

with the reciprocating lead screw, the transmission nut is sleeved

on the optical shaft, the fixing plate is placed above the

transmission nut, the two guide wheels are respectively fixed on

the fixing plate through the guide wheel fixing rod and butterfly

nut, the two guide wheels are close to each other, and a guide hole

for cables is formed in the middle. The utility model has the

advantages of simple and compact structure, convenient maintenance,

orderly cable arrangement, improved cable arrangement efficiency

and low cost.

20 Ton Best Design Ship Variable Speed Winch with Spooling Device

| No: | Wire diameter(mm) | Pulling Force(KN) | Rotation Direction | Drum Diameter(mm) | Drum Length(mm) |

1 | 3~8 | 3~10 | Lefthand,Righthand | >160 | <1000 |

2 | 10~16 | 12~20 | Lefthand,Righthand | >320 | <1000 |

3 | 18~24 | 20~80 | Lefthand,Righthand | >480 | <1000 |

4 | 26~32 | 100~120 | Lefthand,Righthand | >640 | <1000 |

5 | 34~40 | 150~200 | Lefthand,Righthand | >800 | <1000 |

6 | 42~50 | 240~400 | Lefthand,Righthand | >1000 | <1000 |

Product name | Cable winch drum |

Drum Quantity | Single Or Double |

Drum Design | LBS Groove Or Spiral Groove |

Material | Carbon Stainless And Alloy Steels |

Size | Customization |

Application Range | Construction Mining Terminal operation |

Power Source | Electric and hydraulic |

Rope Capacity | 100~300M |

Product Features:

1. Steel Wire rope electric winch with spooling system

2. Automatic rope arrangement can be realized

3. Compact structure and reasonable design

4. Keep the wire rope's tensioning tight for winches & cranes

5. The spooling machine can supply a back force on the rope to keep

the rope a tensioning force.The spooling machine and its HPU are

removeable

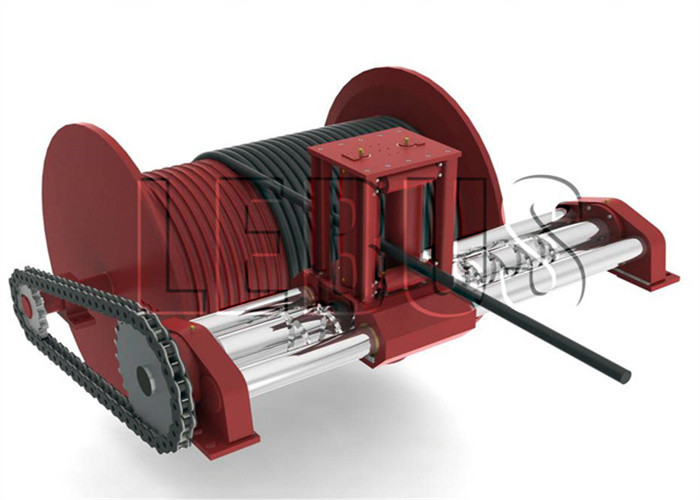

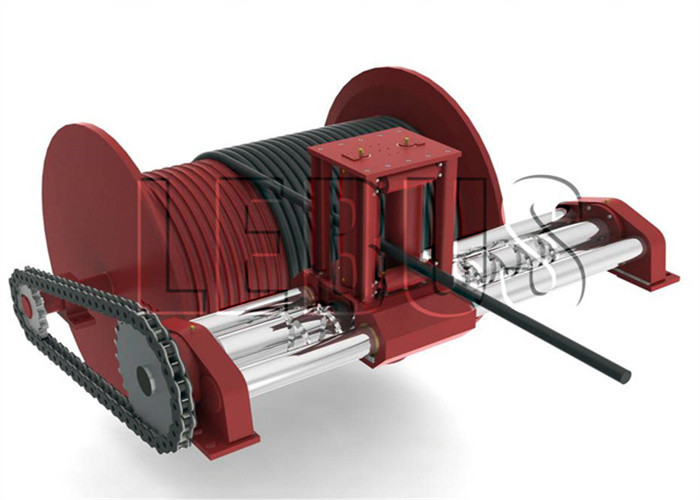

Spooling device:

1. The rope winding device of the winch (spooling device winch) adopts the principle of double rotating screw to drive the

rope wheel to move back and forth,It is mechanical transmission

device, easy to use, safe and reliable.

2. The winch rope arranging device consists of six parts, namely,

power output part, transmission box, clutch, spiral sleeve part,

rope supporting part and base.

3. In the installation process, does not require any part of the

transformation of the winch, only needs to install the outer gear

on the winch motor side, the power of the motor output.

Drive principle:

Winch drum - gear box - screw sleeve rotation - rope wheel

reciprocating movement.

Our Service

All products purchased in our company are guaranteed to keep in

good repair for one year.

If quality problems happen in guarantee period, our company will

maintain for free.

a. Before sending the machine, we will test and adjust, so you can

use directly when you get it.

b. Operation video & instruction will be sent to clients, to help

them use the machines better.

Additionally, our company provides technical support and fittings

for life. After-sales service isn't restricted by time and we

will solve your problems in time.

If you are caught in some problems when using our products, welcome

to contact us at any time.

a. Any problems occur while using, professional advice will be

offered.

b. All kinds of frequently used parts are supplied all the year

round.

Company introduction

Our company early introduction of advanced technology at home and

abroad, after years of research and development and improvement, in

the hoisting machinery multi-layer wire rope row rope field has

made a major breakthrough,

In 2010, the company obtained the production patent of double

folding rope groove drum, and founded its own brand - LBS. At

present, the company has formed a mature and stable,

serializedproduct production mode.

When the split type drum fence skin is installed, the split fence

skin sleeve is wrapped on the smooth slotless drum, and is closely

connected with the drum through bolts or welding, so that the

original smooth surface of the drum outside the surface becomes the

form of lebus double folding rope groove, which is convenient for

the application of winch modification or replacement of the drum.

Our factory has more than 2000 sets of advanced equipment such as

casting, forging, gear processing, sheet metal stamping, riveting,

heat treatment and mechanical processing. In recent years, the

Germany CW1000 machining center, CNC four axis, five axis linkage

machining center, CNC punch, large CNC hobbing gear grinding

machine, large CNC floor boring and milling machine,Vacuum electron

beam welding, CNC welding robot and 80 roll machine and other

advanced processing equipment.