Hebei Junke Machinery Technology Co.,Ltd

Hebei Junke Machinery Techonlogy Co., Ltd was established in 2010.

Now it is located in Shijiazhuang city, Hebei province, China. Our

company covers more than 10000 square meters and it has very

convenient transportation. There are more than 300 existing staff

members among who are 100 profressional technicists. We

also have skilled workers and advanced processing equipments.

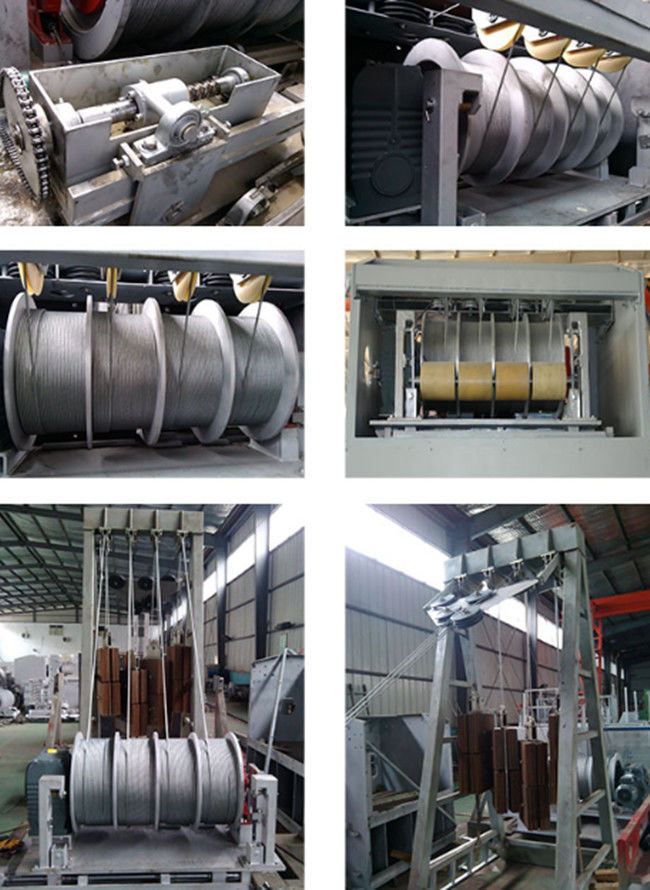

Our factory has more than 2000 sets of casting, forging, gear

machining, sheet metal stamping, welding, heat treatment,machining

and other advanced equipments. In recent years, we have introduced

80 machines of Germany CW1000 processing center, CNC four

axis,five-axis linkage machining center, CNC punching machine,large

CNC gear hobbing gear grinding machine, large CNC floor-type boring

and milling machine, vacuum electron beam welding, CNC welding

robots and other advanced processing equipments.

Our factory always adhere to business idea of "Honesty and

Credibility&Customer First". With high reputation, high quality

products and a competitive price policy ,we provide our customers

with satisfactory services.

We hope to establish long-term and stable business cooperation

with domestic and foreign customers!