Compared with the general non grooved (smooth) drum and spiral

grooved drum, the Grooved Steel Drum Sleeves has obvious advantages

in the neat winding of multi-layer steel wire rope. Lbs double fold

rope groove makes the winding of steel wire rope more smooth and

the load between layers is evenly distributed, reduces the

irregular, disorderly winding and rope biting in the process of

steel wire rope arrangement, reduces the damage of steel wire rope,

prolongs the service life of steel wire rope, improves the safety

of equipment operation, and avoids the shutdown time of mechanical

equipment due to disorderly rope replacement.

Our factory has more than 2000 sets of advanced equipment such as

casting, forging, gear processing, sheet metal stamping, riveting,

heat treatment and mechanical processing. In recent years, the

Germany CW1000 machining center, CNC four axis, five axis linkage

machining center, CNC punch, large CNC hobbing gear grinding

machine, large CNC floor boring and milling machine, Vacuum

electron beam welding, CNC welding robot and 80 roll machine

Product Introduction

Grooved Winch Drum Material: Carbon Steel, Alloy Steel, Stainless

Steel, Aluminum, High-Strength Steel, Etc

Material Standards: GB, AISI, ASME, ASTM, JIS, DIN, ...

Ambient Temperature: -40 ° C To +45 ° C

Stroage Ambient Temperature: -40 ° C To +50 ° C

Groove Type of Drum: Spiral Grooves or Lebus Grooves

The Rotation Direction of The Drum: Lefthand or Righthand

Processing method: Machine Work

Wire Rope Diameter: 3 MM~100 MM

Processing Equipment: CNC machining center

Groove Drum Composition: Drum core, Flanges, Shaft, Etc

Processing: Rope drums with grooves cut directly into them.Winch

drum with flange, the LBS groove is cut directly into the body of

the

drum, according to customers’ requirements, the flanges are either

welded or screw-bolted. groove geometry is determined by rope

construction, diameter and length, and by application. the drum has

the required mounting dimensions for the actual operating

conditions.

Product Application:

1. Offshore Marine machinery: Offshore petroleum crane winch,

Mooring winch, Traction winch, Man-riding winch, Anchor winch,

Hydrologic winch

2. Engineering machinery: Cable winch, Tower crane, Piling machine,

Hydraulic winch

3. Oil field industry: Oil drilling rig, Petroleum tractor hoist,

Petroleum workover rig, Trailermounted pumping unit winch , Logging

winch, etc

4. The building machinery: Building wipe wall winch, Winding hoist,

Windlass

5. Mining winch: Dispatching winch, Prop-pulling winch,Sinking

winch, etc

6. Crane machinery: The bridge lifting machine, Tower crane, Gantry

crane,Crawler crane winch

About Size:

We can manufacture all sizes of drums. From now, we have finished

the drums from 50mm to 2000mm in diameter. And its length range is

from 100mm to 2000mm.

Some Technical Parameters

No: | Wire diameter(mm) | Pulling Force(KN) | Rotation Direction | Drum Diameter(mm) | Drum Length(mm) |

1 | 3~8

| 3~10 | Lefthand,Righthand | >160 | <1000 |

2 | 10~16

| 12~20 | Lefthand,Righthand | >320 | <1000 |

3 | 18~24

| 20~80 | Lefthand,Righthand | >480 | <1000 |

4 | 26~32

| 100~120 | Lefthand,Righthand | >640 | <1000 |

5 | 34~40

| 150~200 | Lefthand,Righthand | >800 | <1000 |

6 | 42~50

| 240~400 | Lefthand,Righthand | >1000 | <100 |

LBSS Series Grooved Sleeves(Shell)

Split-sleeve consists of a pair of outer shells that are bolted or

welded onto a smooth drum. We can manufacture spiral groove and

lebus groove.

The split-sleeve depends on the drum’s size,wire rope diameter and

length.

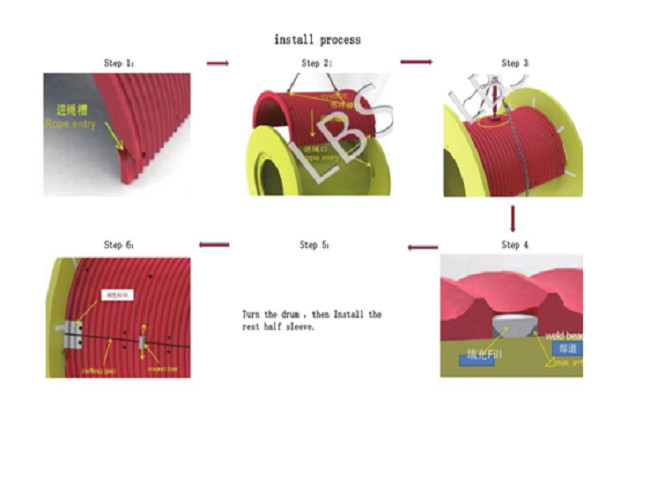

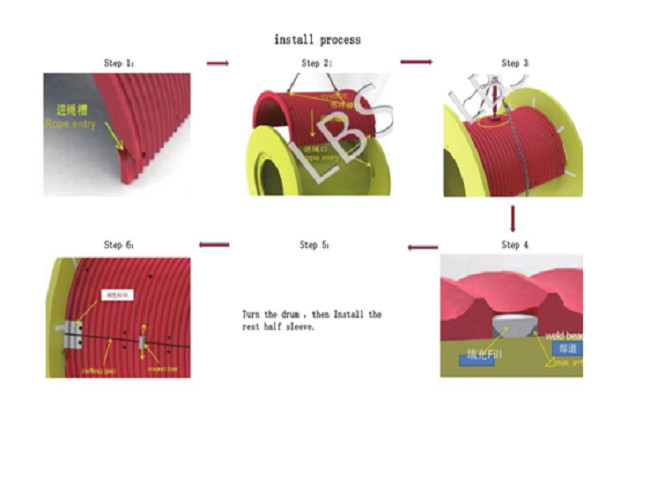

Installation details:

Company introduction

Our company early introduction of advanced technology at home and

abroad, after years of research and development and improvement, in

the hoisting machinery multi-layer wire rope row rope field has

made a major breakthrough,

In 2010, the company obtained the production patent of double

folding rope groove drum, and founded its own brand - LBS. At

present, the company has formed a mature and stable,

serializedproduct production mode.