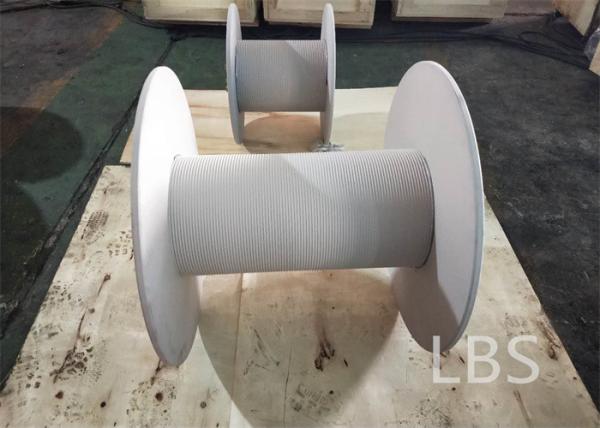

Tower Crane Equipment 12mm DIA Wire Rope LBS Grooved Winch Drum

A basic description

Tower crane is referred to as tower crane, also known as tower

crane, originated in Western Europe. A rotating crane with arms

mounted on top of a towering tower. Large working space is mainly

used for vertical and horizontal conveying of materials and

installation of building components in building construction. It is

composed of metal structure, working mechanism and electrical

system. The metal structure includes tower body, boom and base. The

working mechanism has four parts: lifting, luffing, turning and

walking. Electrical system includes motor, controller, power

distribution cabinet, connecting circuit, signal and lighting

device, etc

| The basic information |

| ame | Tower crane |

| the alias | Tower hoist |

| origin | Western Europe |

| use | Vertical and horizontal conveying of materials in construction |

| classification | Upper rotary tower and lower rotary tower |

overview

Grooved Winch Drum Material: Carbon Steel, Alloy Steel, Stainless

Steel, Aluminum, High-Strength Steel, Etc

Material Standards: GB, AISI, ASME, ASTM, JIS, DIN, ...

Ambient Temperature: -40 ° C To +45 ° C

Stroage Ambient Temperature: -40 ° C To +50 ° C

Groove Type of Drum: Spiral Grooves or Lebus Grooves

The Rotation Direction of The Drum: Lefthand or Righthand

Processing method: Machine Work

Wire Rope Diameter: 3 MM~100 MM

Processing Equipment: CNC machining center

product information

|

| Hoist speed | 0.95-1.27m/s |

| Rotate speed | 720-960 r/min |

| Rope diameter | 3-30mm |

| Sling type | wire |

| Direction rotation | left or right |

| Application | hoist |

| Parameter | can be designed |

| Application | mining,oil drilling,or coal mine |

| Drum diameter | 900mm |

| Drum width | 600mm |

Advantages :

LEBUS drum has a special key, is designed at the bottom of the reel

end flange (end insert) and extension pieces, they guide the wire

rope from the first layer to the second layer smoothly.

The lebus groove makes the load evenly distributed between layers,

and the practice proves that the service life of the wire rope is

greatly prolonged. In fact, the test surface can extend wire rope

life by more than 500%. Reducing wire rope damage increases safety

and reduces machine downtime.

Processing type :

Lebus grooved drum

The groove is cut directly into the body of the drum.(according to

customer‘s requirements.

The flanges are either welded or screw-bolted.)

Split-lebus grooved sleeves (shell )

The whole lebus grooved drum is divided into the upper and lower

parts,which we call them lebus split-sleeves. The sleeves are

available a smooth drum or helical drums.

LBSD Series Grooved drum :

About Size:

We can manufacture all sizes of drums. From now, we have finished

the drums from 50mm to 2000mm in diameter. And its length range is

from

100mm to 2000mm.

Some parameters of drums:

| Rope diameter(mm) | 5 12 24 32 42 58 |

| Grooved drum diameter(mm) | 80 150 300 500 800 1100 |

| Width between the flanges flanges(mm) | 150 280 300 460 750 1000 |

| Rotation direction | L R R L L R |

| Number of layers | 3 2 4 6 8 8 |

| Rope capacity(m) | 18 19 43 127 360 1800 |

Our equipment

Our factory has more than 2000 sets of advanced equipment such as

casting, forging, gear processing, sheet metal stamping, riveting,

heat treatment and mechanical processing. In recent years, the

Germany CW1000 machining center, CNC four axis, five axis linkage

machining center, CNC punch, large CNC hobbing gear grinding

machine, large CNC floor boring and milling machine, Vacuum

electron beam welding, CNC welding robot and 80 roll machine and

other advanced processing equipment.